Central Medical Compressed Air

- Home

- Central Medical Compressed Air

Central Medical Compressed Air

Medical compressed air is used in hospitals to drive ventilators and to combine it with oxygen and breathing of patients. It is also used for nebulizer drugs and as an agent for chemotherapy drugs. Another use of compressed air is, of course, with higher pressures (about 10 bar) in operating rooms for surgical equipment and tools. Therefore, the air quality of the compressed air system is very important and it should be very clean and free of any pollutants and odors based on the Iranian national standard 11636-1 and the international standard ISO7396-1.

Based on the Iranian national standard and the international standard, three types of air compressors can be used to supply compressed air to hospitals.

Piston compressors

Oil screw compressors

Dry scroll compressors

In addition to the air compressor, the medical compressed air device must be equipped with air purification equipment and a monitoring system. The meaning of air purification system is the equipment that, while drying the compressed air to -40 degrees Celsius dew point, cleans the air from dust and odor to be in class 1.1.1 of the international standard ISO8573-1.

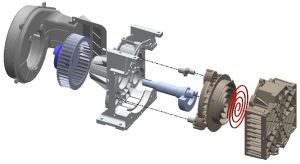

Medical compressed air system equipped with scroll compressor

In this system, the use of which is mandatory in the American NFPA standard, the source of compressed air supply is a scroll type compressor that compresses air up to 10 bar pressure without the need for oil. As you can see in the figure below, the air is compressed by being trapped between the two snails involved, and no oil is used in the compression process. Therefore, in this method, consumable parts such as oil, oil filter and oil separator are removed in the maintenance of the device and its costs will be much lower.

Advantages:

Easy maintenance

Low management and maintenance cost

Lower risk

Longer lifespan

Possibility of 24-hour use in medical centers

The possibility of providing all the required capacities of medical centers

Disadvantages:

The only drawback of these systems is the higher price

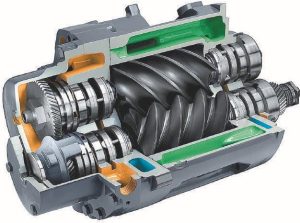

Medical compressed air system equipped with Oil Injected Screw Compressor

In this type of systems, oil screw compressors are used, which use oil as a lubricant in the process of producing compressed air, and then the oil is separated from the air by filters and separators. It is normal that after the air exits from the compressor, the air will be completely dry and oil-free by the filters and microfilters installed in the air purification system and will be in class 1.1.1 of the ISO8573-1 standard. The use of this system is completely prohibited in the NFPA standard, but it is allowed in the European standard, but the air entering the intake line must be completely free of any pollution and must be in class 1.1.1 of the ISO8573-1 standard.

Advantages:

Lower purchase cost

More variety of manufacturers

Can be used 24 hours a day

The possibility of providing all the required capacities of medical centers

Disadvantages:

Higher risk of not having clean air

Higher cost of maintenance and service

Medical compressed air system equipped with oil and dry piston compressor

Piston compressors can usually be used for low capacities and in small size medical centers and limited surgery. Due to the structure of piston compressors, they are usually not recommended for centers that need 24-hour air supply with maximum capacity.

Advantages:

Lower price in low capacities

Smaller dimensions

Disadvantages:

Need more care in maintenance

Higher maintenance cost compared to screw and scroll compressors

Higher risk of failure compared to other compressors

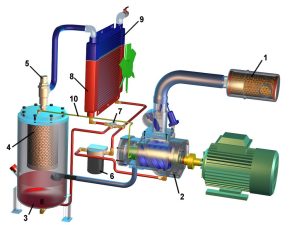

Medical air purification system

According to the national standard of Iran 11636-1 and the international standard ISO7396-1, the compressed air produced by this equipment must have the following quality characteristics:

Oxygen concentration between 21.4% and 20.4% volume fraction

The total amount of oil is less than 0.1 mg/m3

The moisture content or dew point of the outgoing air is less than (-44) degrees Celsius or less than 67 ml/m3

The amount of allowed pollutant particles (according to ISO 8573 standard)

A- Particles with a diameter of 0.1 to 0.5 microns, maximum 100 pieces

B- Particles with a diameter of 0.5 to 1 micron, maximum 1 number

C- Particles with a diameter of 1 to 5 microns should not exist at all

The amount of carbon monoxide is less than 5 ml/m3

The amount of carbon dioxide is less than 500 ml/m3

(NO + NO2) less than 2 ml/m3

The amount of SO2 is less than 1 ml/m3

Therefore, to achieve such a quality, you must use the combination of absorption dryer and filtration below. Unfortunately, it can be seen that in some systems, dry refrigeration is used, which can dry the air’s dew point up to 3 degrees Celsius.

Adsorption dryer

1 micron microfilter (PreFilter)

Microfilter 0.01 micron (Submicronic)

Carbon monoxide microfilter (to convert monoxide to carbon dioxide)

0.003 micron active carbon microfilter (Active Carbon)

Dust particle microfilter

Bacteria microfilter

Air pressure for medical compressed air systems is defined in the following number standard:

Compressed medical gases, other than nitrogen or air, for operating surgical equipment

400-500 kPa

Nitrogen or air for operating surgical equipment

700-1000 kPa (a)

vacancy

60 ≤ kPa (b)

(a) For different ranges, national or regional regulations may be required

(b) Absolute pressure

Therefore, when preparing these systems, you should pay attention to the required pressure.

Air Tanks

Air tanks of compressed air systems should be based on ASME Sec VIII Div. I should be designed and manufactured, and the steel approved by this standard is A516 Gr70, which is sometimes seen in Iran, cheaper steels are used to build tanks, which unfortunately will bring many risks to medical centers.

When choosing and buying these systems, several things must be taken into consideration, such as the height of the installation location above sea level, relative humidity, and maximum temperature. The sales engineers of this company are ready to provide medical centers with the necessary information for purchase engineering and correct selection of devices for free, so contact us before purchasing.